Multiple Exxon/Sunoco Gas Stations

Cranbury and Florence Township, New Jersey

BANC3 performed environmental remediation and construction administration, including the removal and replacement of underground storage tanks (UST), for several gas station facility upgrades. Each site was evaluated to determine if releases from the USTs had impacted the environment. Extensive remedial investigations and remediation were conducted at the sites and significant contamination was identified at most. Free product recovery systems, both passive absorption and active pumping, have been installed.

In-site remediation of soil and groundwater, including passive remediation using oxygen release compounds injected into the subsurface, were utilized. Evaluations of natural attenuation via the ASTM RBCA process were used to determine the cost-effective resolution for each site. The project demonstrates our ability to execute a complex project using state-of-the-art remediation techniques.

BANC3 surveyed the sites and assessed unique site needs; developed design documents for removal and replacement of USTs; applied for and acquired necessary approvals for all disciplines; scheduled the project, coordinated resources, performed construction and environmental inspections and assessments; designed the construction of spill containment systems to meet SPCC requirements; responded quickly at one of the sites in removing contaminated soil; identified, delineated, and designed remedial systems, and remediated contamination; obtained NJDEP case closure; and completed all required NJDEP reports.

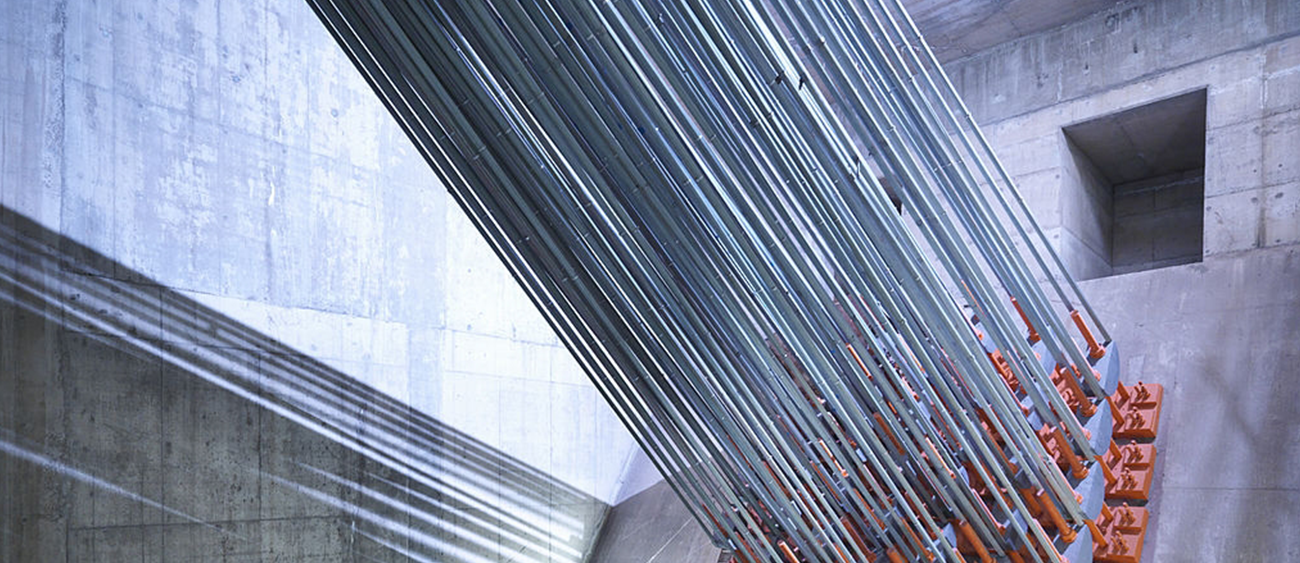

One of the projects involved the excavation and removal of contaminated soil and demolition of an existing building at the Mobil Gas Station in Cranbury, NJ. This project was performed utilizing the services of a subcontracted excavator. The building foundations removed were constructed of nearly two foot thick concrete walls and extended beyond the buildings footprint. This condition was unknown during the pre-construction phase and could only be addressed with heavier equipment and additional time. We completed the project on time, after an extension had been granted based upon the unanticipated conditions. There were no safety violations or problems associated with our work.